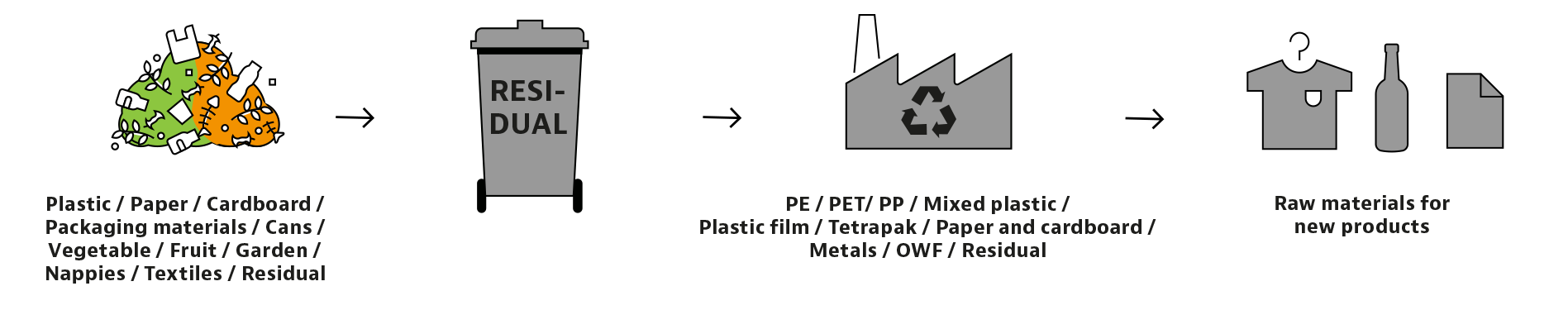

Household waste plant

The purpose of the plant is to separate hard plastics, foils, metal, paper and organic wet fraction from household residual waste as efficiently as possible. Each step in the separation process is geared to create several recyclable products that are reused as raw materials through further reprocessing.

Much higher gas yield

Basically, the separation plant consists of a reducer, sieves, magnets, wind shifters, ballistic separators and near-infrared (NIR) scanners. The smallest fraction (0-70mm) is the organic wet fraction (OWF). It is possible to ferment the OWF fraction integrally or to reprocess it via our OWF reprocessing plant into mono-streams, like glass, plastics, metals and stone. The residue is an organic fraction with a much higher gas yield.

The fractions larger than 70 mm are passed through a separation plant, where the material is first separated into 2D and 3D streams. The 2D stream consists of flat parts, like foils, paper and textiles. The 3D stream is dimensionally stable materials (i.e. materials that keep their shape), like hard plastics and drinks cartons.

In the 2D stream, paper and foils are separated quantitatively using wind shifting. Qualitatively, the paper and foil fraction can be further processed by NIR scanners.

Hard plastics are separated from the 3D stream using NIR scanners, and where necessary, iron or non-ferrous metals and drinks cartons are removed from the stream using magnets. An NIR scanner separates plastics up to the level of PET, PP and PE.